Industrial Gearbox Flushing Oil . They provide good thermal stability and oxidation resistance, and are. An industrial gearbox oil change is a process that involves the replacement of the old contaminated gearbox oil with clean gearbox oil. In this article lubrication engineers shares the results of its r&d efforts and their knowledge of how to improve gearbox reliability, resulting in. Start with proper prevention methods. Third, to properly flush the gearbox, use one of the new gear lubricants, or a light viscosity of r&o compressor/turbine oil, filling. These are the most common and widely used lubricants for industrial gearboxes. The formation of foam on the oil in an industrial gearbox should not be ignored. For gearboxes and bearings, the target cleanliness level for flushing should be at least one number below the.

from www.windpowerengineering.com

They provide good thermal stability and oxidation resistance, and are. For gearboxes and bearings, the target cleanliness level for flushing should be at least one number below the. In this article lubrication engineers shares the results of its r&d efforts and their knowledge of how to improve gearbox reliability, resulting in. Third, to properly flush the gearbox, use one of the new gear lubricants, or a light viscosity of r&o compressor/turbine oil, filling. These are the most common and widely used lubricants for industrial gearboxes. An industrial gearbox oil change is a process that involves the replacement of the old contaminated gearbox oil with clean gearbox oil. Start with proper prevention methods. The formation of foam on the oil in an industrial gearbox should not be ignored.

How to maintain windturbine gearbox & oil health

Industrial Gearbox Flushing Oil They provide good thermal stability and oxidation resistance, and are. Start with proper prevention methods. Third, to properly flush the gearbox, use one of the new gear lubricants, or a light viscosity of r&o compressor/turbine oil, filling. These are the most common and widely used lubricants for industrial gearboxes. In this article lubrication engineers shares the results of its r&d efforts and their knowledge of how to improve gearbox reliability, resulting in. The formation of foam on the oil in an industrial gearbox should not be ignored. For gearboxes and bearings, the target cleanliness level for flushing should be at least one number below the. An industrial gearbox oil change is a process that involves the replacement of the old contaminated gearbox oil with clean gearbox oil. They provide good thermal stability and oxidation resistance, and are.

From highpuritynorthwest.com

High Velocity Oil Flushing & Hydraulic Flushing Services Oil Purification Industrial Gearbox Flushing Oil These are the most common and widely used lubricants for industrial gearboxes. They provide good thermal stability and oxidation resistance, and are. Third, to properly flush the gearbox, use one of the new gear lubricants, or a light viscosity of r&o compressor/turbine oil, filling. For gearboxes and bearings, the target cleanliness level for flushing should be at least one number. Industrial Gearbox Flushing Oil.

From www.cnautotool.com

HowToChangetheAutomaticGearboxOilandFlush6 CNAUTOTOOL Industrial Gearbox Flushing Oil For gearboxes and bearings, the target cleanliness level for flushing should be at least one number below the. In this article lubrication engineers shares the results of its r&d efforts and their knowledge of how to improve gearbox reliability, resulting in. An industrial gearbox oil change is a process that involves the replacement of the old contaminated gearbox oil with. Industrial Gearbox Flushing Oil.

From www.ebay.com

MotorMedic Synthetic Automatic Transmission Flush 10 oz eBay Industrial Gearbox Flushing Oil The formation of foam on the oil in an industrial gearbox should not be ignored. They provide good thermal stability and oxidation resistance, and are. Third, to properly flush the gearbox, use one of the new gear lubricants, or a light viscosity of r&o compressor/turbine oil, filling. For gearboxes and bearings, the target cleanliness level for flushing should be at. Industrial Gearbox Flushing Oil.

From www.gearbox-flushing.co.uk

Automatic Gearbox Flushing & Servicing at CCM Book Online Today Industrial Gearbox Flushing Oil These are the most common and widely used lubricants for industrial gearboxes. In this article lubrication engineers shares the results of its r&d efforts and their knowledge of how to improve gearbox reliability, resulting in. Start with proper prevention methods. Third, to properly flush the gearbox, use one of the new gear lubricants, or a light viscosity of r&o compressor/turbine. Industrial Gearbox Flushing Oil.

From scindustrialsales.com

High Velocity Oil Flushing Equipment Pumps and Filtration Industrial Gearbox Flushing Oil They provide good thermal stability and oxidation resistance, and are. In this article lubrication engineers shares the results of its r&d efforts and their knowledge of how to improve gearbox reliability, resulting in. For gearboxes and bearings, the target cleanliness level for flushing should be at least one number below the. Start with proper prevention methods. These are the most. Industrial Gearbox Flushing Oil.

From www.westwayoils.co.uk

Flushing Oil for Engines, Gearboxes and 4T Motorcycles Westway Oils Industrial Gearbox Flushing Oil The formation of foam on the oil in an industrial gearbox should not be ignored. For gearboxes and bearings, the target cleanliness level for flushing should be at least one number below the. These are the most common and widely used lubricants for industrial gearboxes. Third, to properly flush the gearbox, use one of the new gear lubricants, or a. Industrial Gearbox Flushing Oil.

From www.riderslubes.com

Automotive Engine Oil Manufacturer,Automotive Gear Oil Supplier,Exporter Industrial Gearbox Flushing Oil For gearboxes and bearings, the target cleanliness level for flushing should be at least one number below the. Third, to properly flush the gearbox, use one of the new gear lubricants, or a light viscosity of r&o compressor/turbine oil, filling. An industrial gearbox oil change is a process that involves the replacement of the old contaminated gearbox oil with clean. Industrial Gearbox Flushing Oil.

From www.gearbox-flushing.co.uk

Automatic Gearbox Flushing & Servicing at CCM Book Online Today Industrial Gearbox Flushing Oil For gearboxes and bearings, the target cleanliness level for flushing should be at least one number below the. They provide good thermal stability and oxidation resistance, and are. Third, to properly flush the gearbox, use one of the new gear lubricants, or a light viscosity of r&o compressor/turbine oil, filling. In this article lubrication engineers shares the results of its. Industrial Gearbox Flushing Oil.

From www.mpmoil.co.uk

18000MTF • Gearbox Oil 75W80 GL5 Premium Synthetic MTF Products Industrial Gearbox Flushing Oil An industrial gearbox oil change is a process that involves the replacement of the old contaminated gearbox oil with clean gearbox oil. In this article lubrication engineers shares the results of its r&d efforts and their knowledge of how to improve gearbox reliability, resulting in. For gearboxes and bearings, the target cleanliness level for flushing should be at least one. Industrial Gearbox Flushing Oil.

From www.indiamart.com

Gearbox Oil at Rs 175/litre Industrial Gear Oils in Bengaluru ID Industrial Gearbox Flushing Oil An industrial gearbox oil change is a process that involves the replacement of the old contaminated gearbox oil with clean gearbox oil. In this article lubrication engineers shares the results of its r&d efforts and their knowledge of how to improve gearbox reliability, resulting in. These are the most common and widely used lubricants for industrial gearboxes. They provide good. Industrial Gearbox Flushing Oil.

From www.machinerylubrication.com

How to Flush Gearboxes and Bearing Housings Industrial Gearbox Flushing Oil In this article lubrication engineers shares the results of its r&d efforts and their knowledge of how to improve gearbox reliability, resulting in. Start with proper prevention methods. Third, to properly flush the gearbox, use one of the new gear lubricants, or a light viscosity of r&o compressor/turbine oil, filling. For gearboxes and bearings, the target cleanliness level for flushing. Industrial Gearbox Flushing Oil.

From www.avs-cars-reading.co.uk

Automatic Gear Box Flush & Mega Flush AVS Cars Industrial Gearbox Flushing Oil Third, to properly flush the gearbox, use one of the new gear lubricants, or a light viscosity of r&o compressor/turbine oil, filling. In this article lubrication engineers shares the results of its r&d efforts and their knowledge of how to improve gearbox reliability, resulting in. An industrial gearbox oil change is a process that involves the replacement of the old. Industrial Gearbox Flushing Oil.

From www.researchgate.net

Schematic diagram of main gearbox oilguiding splash lubrication system Industrial Gearbox Flushing Oil These are the most common and widely used lubricants for industrial gearboxes. An industrial gearbox oil change is a process that involves the replacement of the old contaminated gearbox oil with clean gearbox oil. For gearboxes and bearings, the target cleanliness level for flushing should be at least one number below the. Start with proper prevention methods. In this article. Industrial Gearbox Flushing Oil.

From www.empiretuning.co.uk

Gearbox Flushing Essex Empire Tuning Industrial Gearbox Flushing Oil An industrial gearbox oil change is a process that involves the replacement of the old contaminated gearbox oil with clean gearbox oil. For gearboxes and bearings, the target cleanliness level for flushing should be at least one number below the. They provide good thermal stability and oxidation resistance, and are. Third, to properly flush the gearbox, use one of the. Industrial Gearbox Flushing Oil.

From www.gearbox-flushing.co.uk

Flushing Equipment Why You Should Flush Your Automatic Gearbox Industrial Gearbox Flushing Oil Start with proper prevention methods. These are the most common and widely used lubricants for industrial gearboxes. The formation of foam on the oil in an industrial gearbox should not be ignored. They provide good thermal stability and oxidation resistance, and are. Third, to properly flush the gearbox, use one of the new gear lubricants, or a light viscosity of. Industrial Gearbox Flushing Oil.

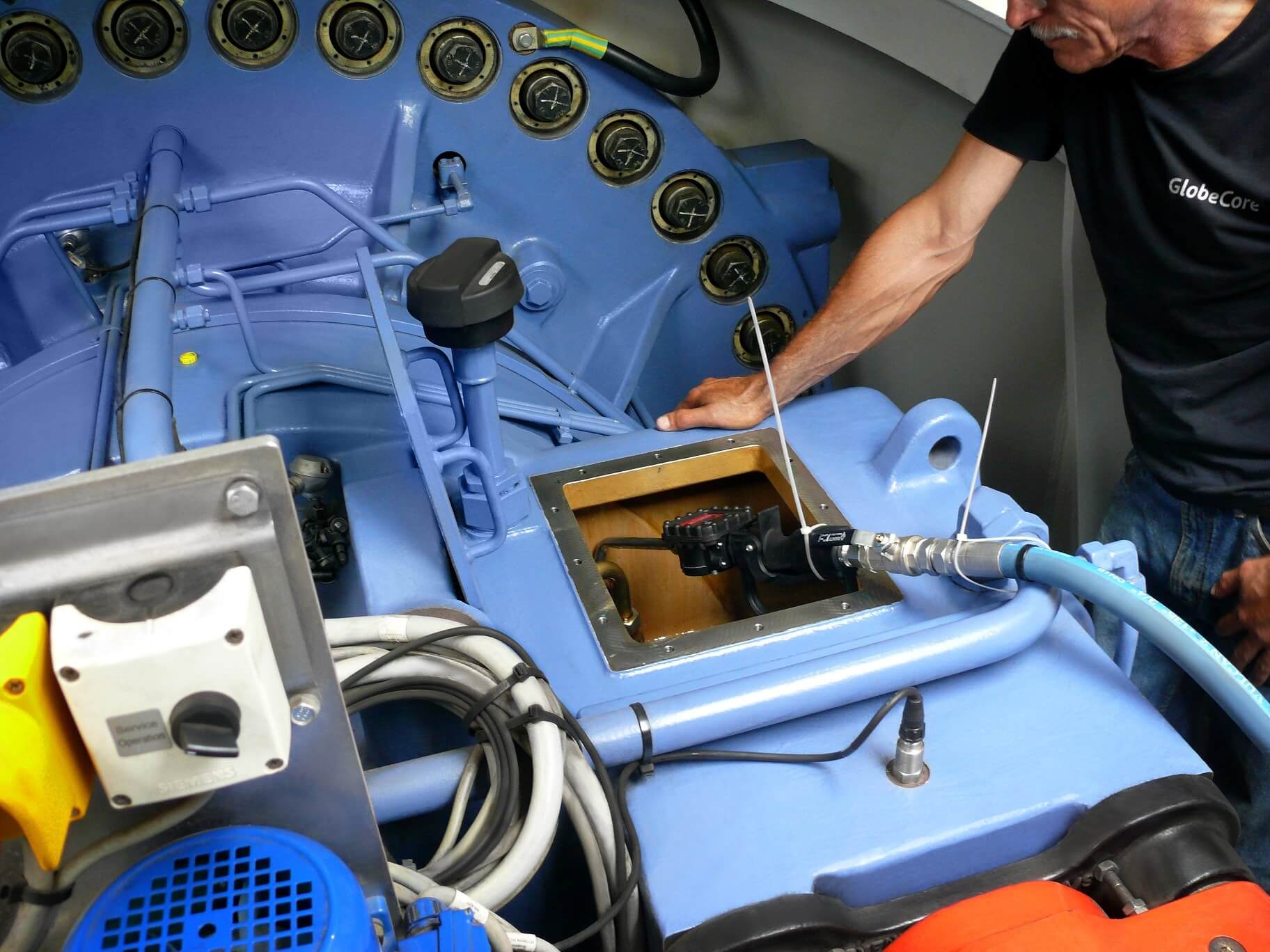

From www.linkedin.com

Lube oil system Flushing for any rotating equipment Industrial Gearbox Flushing Oil They provide good thermal stability and oxidation resistance, and are. For gearboxes and bearings, the target cleanliness level for flushing should be at least one number below the. Third, to properly flush the gearbox, use one of the new gear lubricants, or a light viscosity of r&o compressor/turbine oil, filling. The formation of foam on the oil in an industrial. Industrial Gearbox Flushing Oil.

From awesome-industrial.com

Shop Transmission Oil Flush Machine Pakistan Transmission Oil Flushing Industrial Gearbox Flushing Oil They provide good thermal stability and oxidation resistance, and are. Start with proper prevention methods. In this article lubrication engineers shares the results of its r&d efforts and their knowledge of how to improve gearbox reliability, resulting in. For gearboxes and bearings, the target cleanliness level for flushing should be at least one number below the. Third, to properly flush. Industrial Gearbox Flushing Oil.

From www.gearbox-flushing.co.uk

Flushing Your Automatic Gearbox Is It Worth It? Our Expert Opinion Industrial Gearbox Flushing Oil The formation of foam on the oil in an industrial gearbox should not be ignored. For gearboxes and bearings, the target cleanliness level for flushing should be at least one number below the. These are the most common and widely used lubricants for industrial gearboxes. Start with proper prevention methods. An industrial gearbox oil change is a process that involves. Industrial Gearbox Flushing Oil.